A4 Lead Sealing Screws 316 Stainless High Security Tamper Evident Seal Batch Orders Guanbiao Hardware

Product Details:

| Place of Origin: | China |

| Brand Name: | guanbiao |

| Certification: | ISO9001 |

| Model Number: | M4*38 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 50000 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plastic bag + carton + pallet |

| Delivery Time: | 15-20 work days |

| Payment Terms: | T/T |

| Supply Ability: | 5000000 |

|

Detail Information |

|||

| Security Features: | Tamper-resistant, Anti-theft, Etc. | Salt Spray Test: | 200H |

|---|---|---|---|

| Installation: | Requires Special Tools | Finsh: | Galvanized |

| Drive Type: | Phillips, Torx, Square, Etc. | Button Head Size: | Customizable |

| Finish: | Plain, Black Oxide, Zinc Plated, Etc. | Material: | Stainless Steel |

| Performance: | Non Magnetic | Tooth Lenght: | Customizable |

| Usage: | Indoor/Outdoor | ||

| Highlight: | High Security Lead Sealing Screws,Tamper Evident Lead Sealing Screws,316 A4 Lead Sealing Screws |

||

Product Description

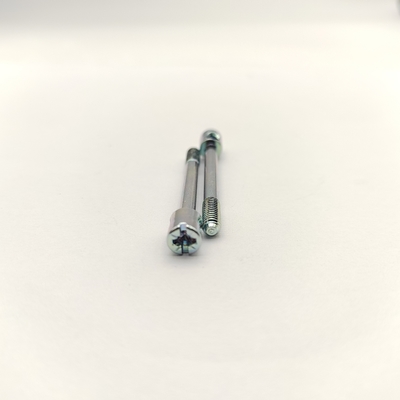

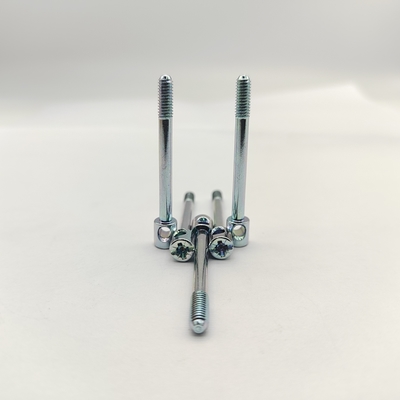

A4 Lead Sealing Screws/ 316 Stainless/ High Security/ Tamper Evident Seal/ Batch Orders Guanbiao Hardware

Premium A4 stainless steel lead sealing screws for maximum security & corrosion resistance. Tamper-evident design for marine, chemical & high-value assets. Passivated finish. Requires seal destruction for removal.

Protect high-value assets and critical infrastructure in corrosive environments with our premium **A4 Stainless Steel Lead Sealing Screws**. Combining the tamper-evident security of a lead seal wire mechanism with the exceptional corrosion resistance of A4 (316) stainless steel, these fasteners are built to last. The robust design, often featuring a hardened drive (e.g., Torx TR) for initial installation and a dedicated, reinforced seal wire path, provides reliable, long-term tamper-proofing for marine equipment, chemical tanks, hazardous material storage, and other demanding security applications.

![]()

TECHNICAL SPECIFICATIONS |

|

| Material | A4 / 316 Stainless Steel (ISO 3506 Class 70 or 80 - **A4-70/A4-80**)l |

| Drive Type | Tamper-Resistant Torx (TR)**, Hex Socket, or Security Pin Hex. *Hardened for durability |

| Head Style | Domed Head, Large Flange Head, or Modified Hex with integrated heavy-duty seal channel |

| Security Feature | Reinforced Collar or Heavy-Duty Hollow Head with hardened steel insert for seal wire. Designed to resist cutting/breaking |

| Strength | High (A4-70: 700 MPa Min Tensile; A4-80: 800 MPa Min Tensile). * **Sizes (Diameter):** Common: M6, M8, M10, M12, M16 |

| Seal Wire Hole Diameter | 2.0mm, 2.5mm (for thicker, harder-to-cut wire) |

| Lengths | Standard & Custom |

![]()

Primary Uses & Applications:

* Marine vessel hatches, valves, and sensitive equipment.

* Offshore oil & gas platform safety valves and access points.

* Chemical processing plant tank lids, sampling ports & valves.

* Hazardous material (HAZMAT) storage containers and transport.

* High-security pharmaceutical storage & processing.

* Military equipment and armory security.

* Critical infrastructure access points (power substations, water treatment).

* High-value cargo containers. * Marine vessel hatches, valves, and sensitive equipment.

* Offshore oil & gas platform safety valves and access points.

* Chemical processing plant tank lids, sampling ports & valves.

* Hazardous material (HAZMAT) storage containers and transport.

* High-security pharmaceutical storage & processing.

* Military equipment and armory security.

* Critical infrastructure access points (power substations, water treatment).

* High-value cargo containers.

Surface Treatment/Finishes:

* **Passivation (Standard):** Critical chemical process to maximize corrosion resistance by removing free iron and enriching the passive chromium oxide layer. Non-conductive.

* **Electropolishing (Optional):** Provides a smoother, brighter surface, further enhances corrosion resistance, improves cleanability, and makes tampering marks more visible.

![]()

How to Use:

1. **Prevent Galling:** Apply a **stainless steel specific anti-seize compound** to the screw threads before installation to prevent seizing.

2. **Install Screw:** Use the **correct security driver** (e.g., TR40 bit for TR drive). Tighten the screw securely to the recommended torque for A4 stainless steel. *Ensure access to the seal wire path remains clear.*

3. **Thread Seal Wire:** Use **stainless steel seal wire** for maximum security and corrosion resistance. Thread through the dedicated hole(s) in the screw's collar/head. Bring ends together.

4. **Apply High-Security Seal:** Use a uniquely **numbered metal seal** or a hardened lead seal. Crimp it securely onto the wire ends using appropriate, calibrated sealing pliers. Ensure the seal number/ID is recorded.

5. **Tamper Evidence:** The seal and wire physically block access to the drive. Removal requires **destructive cutting** of the wire/seal, leaving undeniable evidence. The hardened collar/wire path resists casual cutting.

6. **Inspection & Verification:** Regular visual checks confirm seal integrity. Recorded seal numbers allow for verification against logs. Broken/missing seals indicate tampering.