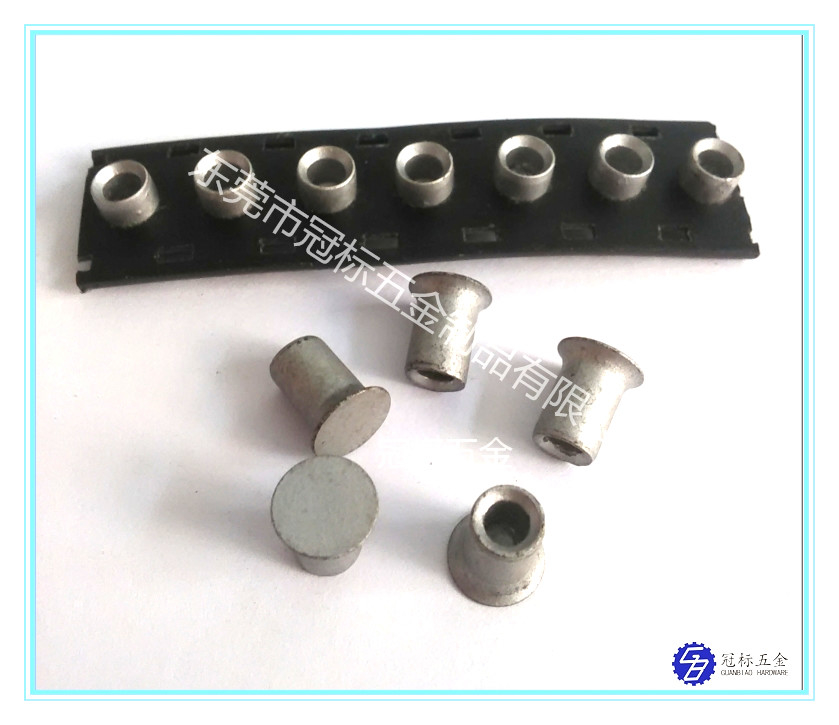

High Strength Self Piercing Rivets Polishing 5.3x7mm 5.3x8mm 5.3x4mm

Product Details:

| Place of Origin: | China |

| Brand Name: | guanbiao |

| Certification: | ISO, GB, BS, DIN, ANSI,JIS |

| Model Number: | 5.3*4;5.3*5;5.3*6;5.3*7;5.3*8 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 200000PCS |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Small box, small color box, export carton, and put on strong wood pallet |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T |

| Supply Ability: | 100000PCS/day |

|

Detail Information |

|||

| Material: | Stainless Steel: 302,304,316 | Production Process: | Cold Heading, Cold Forging |

|---|---|---|---|

| Surface Finish/treatment: | Polishing, Passivation | Tolerant: | +/- 0.05mm |

| MOQ: | 50000 Pieces | Single: | 3.25g/pcs |

| Highlight: | 5.3x7mm self piercing rivets,5.3x8mm self piercing rivets,5.3x4mm high strength rivet |

||

Product Description

5.3*4 High-strength self-piercing rivets 5.3*5 High-Strength Self-piercing Rivets 5.3*6 Alloy Steel Self-piercing Rivets

| Material | Stainless steel, brass, copper, aluminum, aluminum alloy, steel, low carbon steel, medium carbon steel, alloy steel, titanium alloy, etc. |

| Production Process | Cold heading, cold forging, CNC machining, CNC turning, CNC milling, drilling, tapping, grinding, wire cutting |

| Surface finish/treatment | Zinc plating, nickel, chromium, anodizing, sandblasting, painting, powder coating, silk screen, polishing, passivation, laser engraving |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Size |

5.3*4mm |

| Quality assurance | Self-inspection of production technicians |

| Engineer inspection in production | |

| QC inspection after finished product | |

| MOQ | 20000 pieces |

| Payment terms | T/T |

| Shipment | According to customer requirements, it can be delivered by express and sea |

| Lead time | 10~15 working days |

Product image presentation

![]()

![]()

![]()

Four advantages of choosing Guanbiao Hardware

1. More than 20 years of screw production experience and non-standard screw custom development experience, provide you with cost-effective screws, and help you solve the fastener supply chain

2. Precise production equipment. The company introduces all imported equipment from Taiwan to produce precision screws and hardware accessories for you

3. A complete management system, each batch of products that leave the factory undergoes multiple strict monitoring

4. System supporting services, so you have no worries

Precision screw production workshop

![]()

Non-standard custom screws, hardware product production workshop

![]()

Multi-position cold forging machine, the maximum can be customized M20, the minimum can be customized M1.0, the longest can be customized 300mm

![]()

CNC machining center

![]()

![]()

![]()

All of the above products are produced by our company. Most of them have complete sets of molds or some molds. If you find us, you can make money. Welcome to call or add wechat: +86 13423026460