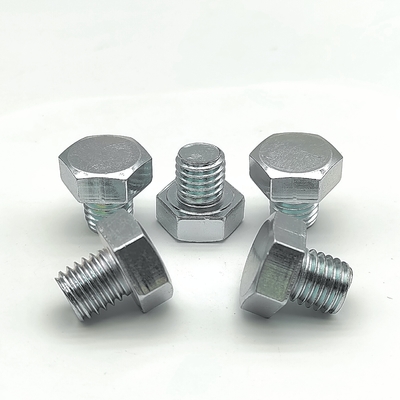

High Strength Hex Head Bolts/ Heavy Machinery & Construction / Alloy & Stainless/ Batch Orders Guanbiao hardware

Product Details:

| Place of Origin: | China |

| Brand Name: | guanbiao |

| Certification: | ISO9001 |

| Model Number: | M3 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 50000 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plastic bag + carton + pallet |

| Delivery Time: | 15-20 work days |

| Payment Terms: | T/T |

| Supply Ability: | 5000000 |

|

Detail Information |

|||

| Thread Length: | Customizable | Quantity: | Available In Bulk Or Small Packs |

|---|---|---|---|

| Finish: | Plain, Black Oxide, Zinc Plated, Etc. | Dimension: | We Can Customise To Your Dimension |

| Market: | Global | Surface Finishing: | Plain |

| Tolerance: | +-0.1mm | Thread Pitch: | Standard Or Custom |

| Diameter: | Various Diameters Available | ||

Product Description

High Strength Hex Head Bolts/ Heavy Machinery & Construction / Alloy & Stainless/ Batch Orders Guanbiao hardware

Reliable high-strength hex head bolts for demanding applications. Available in Grade 8.8, 10.9, 12.9 alloy steel with zinc plating or Dacromet coating. Ideal for construction, machinery & automotive.

Engineered for maximum reliability in high-stress environments, our heavy-duty Hex Head Bolts (Hex Cap Screws) deliver exceptional clamping force and shear strength. Featuring a robust six-sided head designed for wrench or socket application, these bolts provide superior torque transmission and resistance to stripping compared to many drive types. Manufactured from high-strength alloy steels and finished with durable protective coatings, they are the go-to choice for critical structural and industrial applications where failure is not an option.

![]()

TECHNICAL SPECIFICATIONS |

|

| Material | High-Strength Carbon Steel(Grade 8.8 / Grade 5), Alloy Steel (e.g., SCr435, 40Cr, 35CrMo, 42CrMo), Stainless Steel(A2 (304), A4 (316)) |

| Drive Type | Hex Head (External Wrenching) |

| Sizes | Extensive range: M5, M6, M8, M10, M12, M14, M16, M20, M24, M30+ (Metric); #8, 1/4", 5/16", 3/8", 1/2", 5/8", 3/4", 1"+ (Inch). |

| Lengths | Wide variety of standard and custom lengths available |

| Strength Grades | Grade 8.8, 10.9, 12.9 (Metric); Grade 5, Grade 8 (SAE/Inch). (Specify available grades) |

| Thread Types | Full Thread or Partial Thread (Specify grip length options). Metric Coarse (standard), Metric Fine, UNC, UNF |

| Thread Length | Complies with relevant standards for partial thread bolts |

![]()

Primary Uses & Applications:

Hex head bolts excel in applications requiring high clamping force, vibration resistance, and structural integrity:

* Heavy machinery assembly (frames, bases, engines).

* Structural steel construction (beams, columns, bridges).

* Automotive chassis, suspensions, and engine components.

* Agricultural and mining equipment.

* Industrial plant maintenance and fabrication.

* Truck and trailer manufacturing.

* Infrastructure projects (bolted connections).

Surface Treatment/Finishes:

Applied for corrosion protection, lubricity, and appearance:

* **Zinc Plating:** Clear, Blue/White, Yellow, or Black Chromate (most common, economical protection). Meets RoHS.

* **Hot-Dip Galvanizing (HDG):** Thick zinc coating for severe outdoor exposure (e.g., construction, infrastructure). Compliant with ASTM A153.

* **Dacromet / Geomet® (Zinc Flake Coatings):** Superior corrosion resistance (e.g., 500-1000+ hrs salt spray), excellent heat resistance, RoHS compliant. Ideal for automotive and industrial under-hood.

* **Phosphate & Oil:** Provides good lubricity for threading and mild corrosion resistance.

* **Black Oxide:** Decorative finish with mild corrosion resistance and reduced glare.

* **Plain/Oil Finished:** For immediate use or further processing.

How to Use:

Select the correct bolt size (diameter, length, thread type), strength grade, and coating for the application's load and environmental requirements. Use a properly sized hex wrench (spanner) or socket that fits snugly on the bolt head to prevent rounding. Apply torque evenly according to recommended specifications for the bolt grade and size. Always pair with a suitable nut and washer (e.g., hex nut, flange nut, washer) to distribute load and prevent damage to the mating surface. For critical structural applications, follow established torque tightening procedures and consider using calibrated torque wrenches.