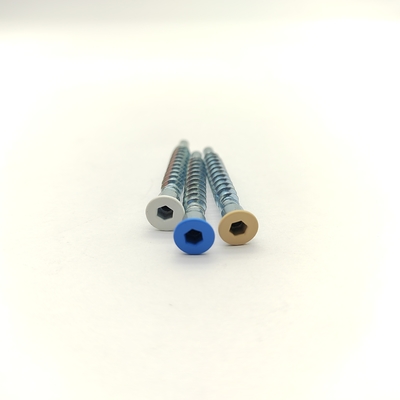

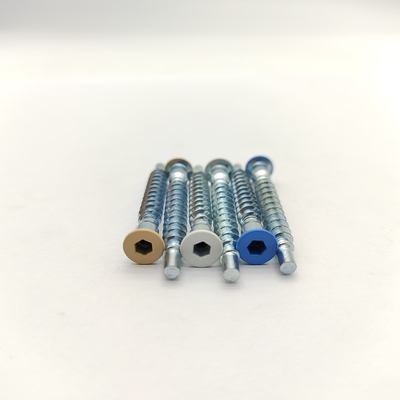

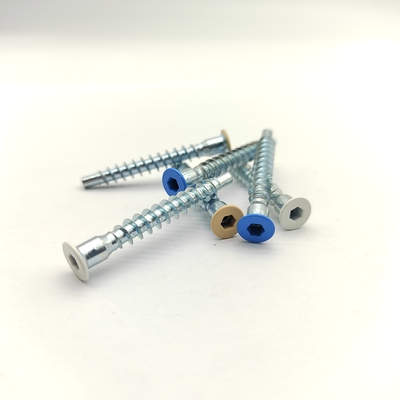

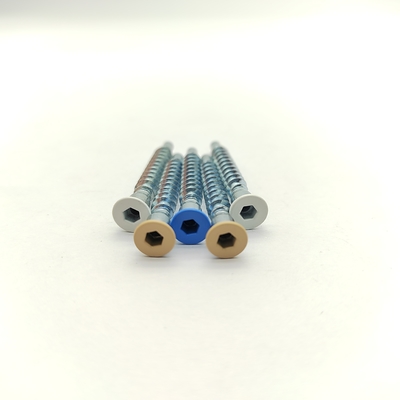

304 SS Furniture Screws Hex Drive Countersunk Self-Tapping Outdoor & Moisture Resistant

Product Details:

| Place of Origin: | China |

| Brand Name: | guanbiao |

| Certification: | ISO9001 |

| Model Number: | M5*20 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 50000 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plastic bag + carton + pallet |

| Delivery Time: | 15-20 work days |

| Payment Terms: | T/T |

| Supply Ability: | 5000000 |

|

Detail Information |

|||

| Materia: | Stainless Steel A2-70 | Tooth Length: | Customizable |

|---|---|---|---|

| Process: | Cold Forging | Durability: | Long-lasting |

| Usage: | Wood, Metal, Plastic | Thread Length: | According To The Drawing |

| Core Hardness: | HV320-450 | Production Process: | Cold Heading, Cold Forging |

| Grade: | 4.8 / 6.8 / 8.8 / 10.9 | Thread Count: | Standard, Customizable |

Product Description

304 SS Furniture Screws Hex Drive Countersunk Self-Tapping Outdoor & Moisture Resistant

Premium A2-70 stainless steel hex socket furniture screws. No rust, ideal for outdoor, bathroom & kitchen furniture. Self-tapping tip, flush countersunk head. Passivated finish. M5-M8 sizes. Durable connections.

Build furniture to last, even in damp or outdoor environments, with our premium **A2 Stainless Steel Hex Socket Countersunk Self-Tapping Furniture Connecting Screws**. Crafted from corrosion-resistant A2-70 (304) stainless steel, these screws resist rust, tarnishing, and moisture damage, making them perfect for outdoor furniture, kitchens, bathrooms, marine interiors, and high-humidity areas. Featuring the same efficient **self-tapping point** and **flush-mounting countersunk head** as our standard screws, they combine ease of assembly with exceptional durability and a sleek appearance. The **hex socket drive** ensures reliable installation without stripping.

![]()

TECHNICAL SPECIFICATIONS |

|

| Material | Carbon Steel (Grade 4.8 or 8.8 equivalent) |

| Drive Type | Hex Socket (Internal Hex / Allen Key) - Common sizes: H4, H5, H6 (M5, M6, M8). |

| Head Style | Countersunk Head (82° / 90° included angle) |

| Point Type | Sharp Self-Tapping Point (Optimized for hardwoods & composites) |

| Surface Finish | Passivated (Standard), Electroplated Nickel optional. |

| Features | Partial thread for clamping, high tensile strength (700 MPa min) |

| Thread Type | Coarse thread pitch for wood composites |

![]()

Primary Uses & Applications:

* High-end indoor furniture (kitchens, bathrooms, luxury cabinets).

* Outdoor & garden furniture (tables, chairs, benches, pergolas).

* Marine cabinetry & boat interior furniture.

* Bathroom vanities & fixtures.

* Furniture for humid climates or spas/saunas.

* Connecting hardware to exotic hardwoods or dense composites.

* Applications requiring a non-corroding, aesthetically clean fastener.

Surface Treatment/Finishes:

* **Passivation (Standard):** Essential chemical process that removes free iron particles and enhances the natural chromium oxide layer, maximizing corrosion resistance. Leaves a clean, slightly matte stainless finish.

* **Electroplated Nickel (Optional):** Provides a bright, silvery finish for enhanced aesthetics and *slightly* improved corrosion resistance. Can reduce galling tendency.

![]()

How to Use:

1. **Prevent Galling (Crucial):** Apply a small amount of **stainless steel specific anti-seize lubricant** or **wax** to the screw threads before installation. This drastically reduces the risk of galling (cold welding/seizing), especially in hardwoods or dense composites.

2. **Align Parts:** Position panels precisely.

3. **Insert & Drive:** Place screw tip on the surface. Insert the **correct size hex key**. Drive the screw at a **90° angle** using **steady, moderate speed and force**. The self-tapping point will cut threads.

4. **Tighten Flush:** Drive until the countersunk head is **fully seated flush** with the material surface. **Avoid excessive RPMs** which generate heat and increase galling risk.

5. **Pilot Holes:** Highly recommended for **hardwoods, near edges/ends, or thick/dense materials**. Drill a pilot hole slightly smaller than the screw's core diameter (approx. 60-70% of shank diameter). This prevents splitting and makes driving easier, reducing galling risk.

6. **Tool Quality:** Use high-quality, sharp hex keys or bits that fit snugly to avoid damaging the socket.